Fancy Twisting Machine Ring Bobbin Composite Dual Color

Delivery term:The date of payment from buyers deliver within days- Price:

Negotiable

- minimum:

- Total supply:

- Delivery term:

The date of payment from buyers deliver within days

- seat:

Jiangsu

- Validity to:

Long-term effective

- Last update:

2025-06-20 11:38

- Browse the number:

282

- Zhangjiagang Kingkangda Machinery Co.,Ltd.

-

Contact:

jinkangda(Mr.)

-

Email:

-

Telephone:

-

Phone:

-

Area:

Jiangsu

-

Address:

Korea Industrial Park, Fenghuang Town, Zhangjiagang City, Jiangsu Province, China

- Website: https://www.kingkangda.com/ http://jinkangda.jczlonico.com/

By certification [File Integrity]

By certification [File Integrity]

Product details

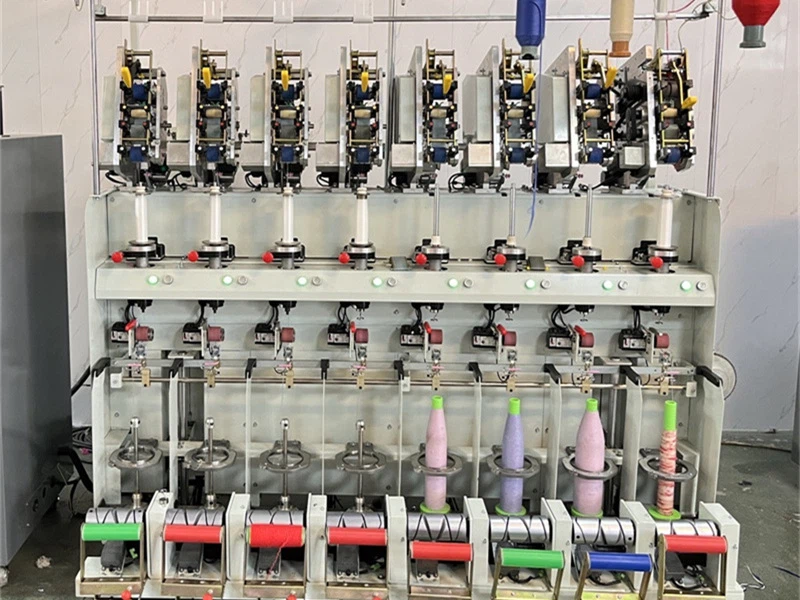

This Fancy Twisting Machine Ring Bobbin Composite Dual Color adopts a dual winding method of ring and grooved drum, a dual drafting system, two-color roving feeding, and a composite spindle. This mechanical configuration not only achieves smooth color blending and gradual transition, but also enriches the variety and structure of yarn. In addition, the equipment also has an intelligent control system that supports recipe memory and independent segment management, which can efficiently customize and mass-produce fancy yarns.

Technical Features

Dual Roving Feeding System

The machine is equipped with an advanced dual-roving feeding system. The drafting system has two rear rollers instead of one. Because each roller is controlled by an independent servo motor, the speed of the two rear rollers can be controlled to support independent feeding of two different colors of roving. This allows for precise color blending, gradient effects, or clear color separations, creating a wider range of fancy yarn styles.

Sectional Yarn Process Flexibility

The machine adopts a segmented structure design, with each segment containing 8 spindles, each of which can operate independently. The first segment can execute 8 different yarn formulas at the same time, and the remaining segments can also be set with different process formulas. In addition, this segmented structure is more convenient for transportation and installation of the equipment. Each segment has a fixed number of sections, making the whole machine more modular.

Independent Servo Drive System

All motors on this machine are controlled by servo motors. Take a spindle as an example. The servo motor on each spindle has core rollers, drafting rollers, including a front roller, a middle roller, two rear rollers, a central control spindle motor, a twisting hook spindle motor, a ring spindle motor and a groove drum winding motor. The core wire tension is controlled by the speed of the core roller and the output roller, the curling tension is controlled by the speed of the output roller and the groove drum motor, the roving feed amount is controlled by controlling the speed of the front roller, and the drafting multiple of the roving is controlled by the speed difference between the front, middle and rear rollers.

Dual Winding Mode

This machine integrates both ring and drum winding to accommodate various yarn winding methods. Ring winding is used for some high-count yarns, as these typically have higher twist. Ring winding, rotating in the opposite direction of the center control spindle, reduces the twist. Low-count yarns, on the other hand, are more often wound using drum winding, which produces a larger yarn volume and provides a more uniform winding pattern.

Composite Spindle Structure for Enhanced Versatility

The hollow spindle and twisting hook spindle are controlled separately, each controlled by a different servo motor, so that the twist of the yarn can be freely increased. Compared with the traditional integrated structure, this design also reduces mechanical vibration and wear.

Fiber Adaptability and Blending

The machine is compatible with a variety of fiber types and lengths, including common natural fibers such as wool, mohair, yak hair, alpaca hair, rabbit hair, yak hair, etc. In addition to the above natural fibers, most chemical synthetic fibers such as polyester, acrylic and spandex can also be processed. The fiber length can be from 30 mm to 200 mm.

Main Technical Parameters

Parameter | Unit | Specification |

Spindles Gauge | mm | 200 |

Number of Spindles | set | 160 |

Hollow Spindle Speed | rpm | 12000 |

Ring Spindle Speed | rpm | 6000 |

Front Roller Speed | m/min | 75 |

Drafting Ratio | / | 0-100 |

Fiber Length | mm | 38-195 |

Roving | g/m | 0.25-2 |

Core Yarn | NM | 1-120 |

Basic Yarn | NM | 1-120 |

Twist range | t/m | 120 to 1250 |

Twist direction | / | S or Z changeable |

Dust Collection | / | Optional |

Power | KW | 38 |

Overall Dimension (Length*width*height) | mm | 27800*1960*2300 |

FAQ

Q1: How is the equipment packaged?

A1: All machines are packed in standard export wooden cases with internal reinforcement, moisture-proofing, and shock protection to ensure safe transportation.

Q2: Does the packaging meet international standards?

A2: Yes. All packaging complies with international export standards and is suitable for customs clearance and transportation in different countries.

Q3: Can you ship the whole machine together with spare parts?

A3: Yes. Customers can choose full machine delivery or spare parts in separate shipments. We will arrange the packaging and loading according to customer requirements.

https://www.kingkangda.com/

-

Drawstring Refuse Sacksvest Style Garbage Bags

Drawstring Refuse Sacksvest Style Garbage Bags

price: Negotiable

-

Desalination Reverse Osmosis

Desalination Reverse Osmosis

price: Negotiable

-

Bypass Sliding Barn Door Hardware Kit

Bypass Sliding Barn Door Hardware Kit

price: Negotiable

-

Fancy Twisting Machine Ring Bobbin Dual Color

Fancy Twisting Machine Ring Bobbin Dual Color

price: Negotiable

-

Dual Rails Manual Tile Cutter Model D

Dual Rails Manual Tile Cutter Model D

price: Negotiable

-

4-(trifluoromethyl)pyrazole 52222-73-8

4-(trifluoromethyl)pyrazole 52222-73-8

price: Negotiable